Research and Analysis on Light Decay of LED Luminaires

Light decay, a perennial issue in the LED industry, has always been a topic of discussion. I've been thinking about how to intuitively convey the relationship between light decay and the lifespan of LED chips to you. Finally, I found a good method, which is to let the pictures speak. Beforehand, let me mention that the key to reducing light decay is heat dissipation...heat dissipation...heat dissipation. It's important, so let's emphasize it multiple times.

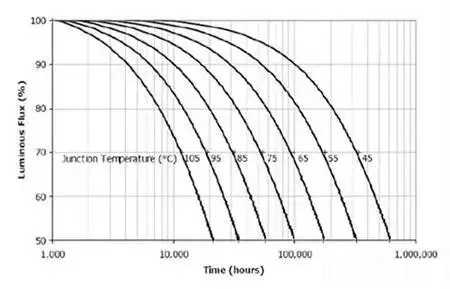

Here is the company's light decay curve:

From the graph, we can see that LED light decay is related to its junction temperature. The so-called junction temperature refers to the temperature of the semiconductor PN junction. The higher the junction temperature, the earlier the light decay occurs, meaning a shorter lifespan. From the graph, if the junction temperature is 105 degrees Celsius, the brightness drops to 70%, and the lifespan is only a little over 10,000 hours. At 95 degrees, it reaches 20,000 hours, while at 75 degrees, the lifespan extends to 50,000 hours, and at 65 degrees, it can even extend to 90,000 hours. So, the key to extending the lifespan is to lower the junction temperature. However, these data are only applicable to our company's LED and may not necessarily apply to LEDs from other companies.

How to Extend the Lifespan of LEDs

So when we purchase LED fixtures (all, not just LED spotlights), we must pay attention to their heat dissipation design.

From the graph, we can conclude that the key to extending the lifespan is to lower the junction temperature. And the key to lowering the junction temperature is to have a good heat sink that can promptly dissipate the heat generated by the LED.

Here, we're not discussing how to design heat sinks but rather which heat sink has relatively better heat dissipation. In reality, this is a temperature measurement problem. If we can measure the junction temperature that any heat sink can achieve, not only can we compare the heat dissipation effects of various heat sinks, but we can also know the LED lifespan achievable with each heat sink.

How to Measure Junction Temperature

Junction temperature seems like a temperature measurement problem, but the temperature we need to measure is inside the LED, so we can't just stick a thermometer or thermocouple into the PN junction to measure its temperature. Of course, we can measure its outer shell temperature with a thermocouple and then calculate its junction temperature based on the provided thermal resistance Rjc (junction to case).

But after installing the heat sink, the problem becomes more complex. Typically, LEDs are soldered to aluminum substrates, which are then mounted on heat sinks. If we can only measure the temperature of the heat sink's outer shell, then to calculate the junction temperature, we need to know many thermal resistance values, including Rjc (junction to case), Rcm (case to aluminum substrate, which should also include the thermal resistance of the thin film printed circuit board), Rms (aluminum substrate to heat sink), and Rsa (heat sink to air), where any inaccuracies in these values affect the accuracy of the test.

The following diagram illustrates the thermal resistances from the LED to the heat sink. Many thermal resistances are combined, limiting their accuracy. In other words, the accuracy of inferring the junction temperature from the measured heat sink surface temperature is even poorer.

Fortunately, there is an indirect method of measuring temperature, which is by measuring voltage. So, which voltage is related to the junction temperature? And what is the relationship like? We need to start with the voltage-current characteristics of LEDs.

We know that an LED is a semiconductor diode, and like all diodes, it has a voltage-current characteristic, which, like all semiconductor diodes, has a temperature characteristic. Its characteristic is that when the temperature rises, the voltage-current characteristic shifts leftward. The graph shows the temperature characteristic of an LED's voltage-current characteristic.

Assuming the LED is supplied with a constant current Io, when the junction temperature is T1, the voltage is V1, and when the junction temperature rises to T2, the entire voltage-current characteristic shifts leftward, with the current Io unchanged, and the voltage becomes V2. The temperature coefficient is obtained by dividing the voltage difference by the temperature and is expressed in mV/°C. For ordinary silicon diodes, this temperature coefficient is approximately -2mV/°C. However, since most LEDs are not made of silicon, their temperature coefficient needs to be separately determined. Fortunately, most LED manufacturers provide this data in their datasheets. For example, for Cree's XLamp7090XR-E high-power LED, its temperature coefficient is -4mV/°C, which is twice that of ordinary silicon diodes. As for arrays of LEDs like those from Bridgelux (BXRA), more detailed data is provided.

However, the data provided by these manufacturers have rather wide ranges, making them less useful. Nevertheless, knowing the LED's temperature coefficient makes it easy to infer the LED's junction temperature from the measured forward voltage of the LED.

How to Predict the Lifespan of this Luminaire

Inferring lifespan from junction temperature seems simple; just check the curve in Figure 1, and you can determine that the lifespan corresponding to a junction temperature of 95 degrees Celsius is 20,000 hours. However, this method has a certain degree of reliability when applied to indoor LED luminaires. If applied to outdoor LED luminaires, especially high-power LED street lights, there are many uncertainties.

The biggest issue is the gradual decrease in the heat dissipation efficiency of the heat sink of LED street lights over time. This is due to the accumulation of dust and bird droppings, which reduces heat dissipation efficiency. Additionally, outdoor environments have strong ultraviolet radiation, which can also reduce LED lifespan. Ultraviolet radiation mainly affects the aging of the encapsulating epoxy resin; however, if silicone gel is used, the situation can be somewhat improved. Ultraviolet radiation also has some adverse effects on phosphors, but they are not very severe.

However, this method is still effective for relatively comparing the heat dissipation effects of two heat sinks. Clearly, the smaller the leftward shift of the voltage-current characteristic, the better the heat dissipation effect of the heat sink. Moreover, it still has a certain degree of accuracy in predicting the lifespan of indoor LED luminaires.

CATEGORIES

LATEST NEWS

- Research and Analysis on Light Decay of LED Luminaires

Light decay, a perennial issue in the LED industry, has always been a to···

- Principles and Prospects of LED Plant Growth Lights

After application testing, the wavelength of the plant light is very sui···

- High-power LED lamp bead parameters and design techniques

BrightnessThe brightness of LEDs varies, affecting their prices:- Bulb c···

- LED 3535 Ceramic Chips: High-Performance Lighting Solution

LED 3535 ceramic chips represent the forefront of lighting technology. A···

CONTACT US

Contact: Mr. Vic

Phone: +86189 2346 0018

Tel: +86 755 2300 7261

Email: vic@hufond-led.com

Add: 4th Floor, Building 2, Huafeng Shenzhen Bao LED Industrial Park, North Ring Road, Shiyan, Bao'an District, Shenzhen, China